Leonardo's Edinburgh journey began as Ferranti during the Second World War, when the War Office – a British Government department responsible for the administration of the British Army from 1857-1964, and forerunner to the Ministry of Defence – identified an urgent need for additional manufacturing capacity.

Since the War Office’s original production plant in Manchester was running out of capacity and having to deal with the constant threat of bombing, a new facility was required to manufacture gyro gunsights for the RAF Spitfire. In just 18 weeks, Ferranti built a new factory at Crewe Toll, Edinburgh. The site remains the home of Leonardo’s radar and advanced targeting systems to this day.

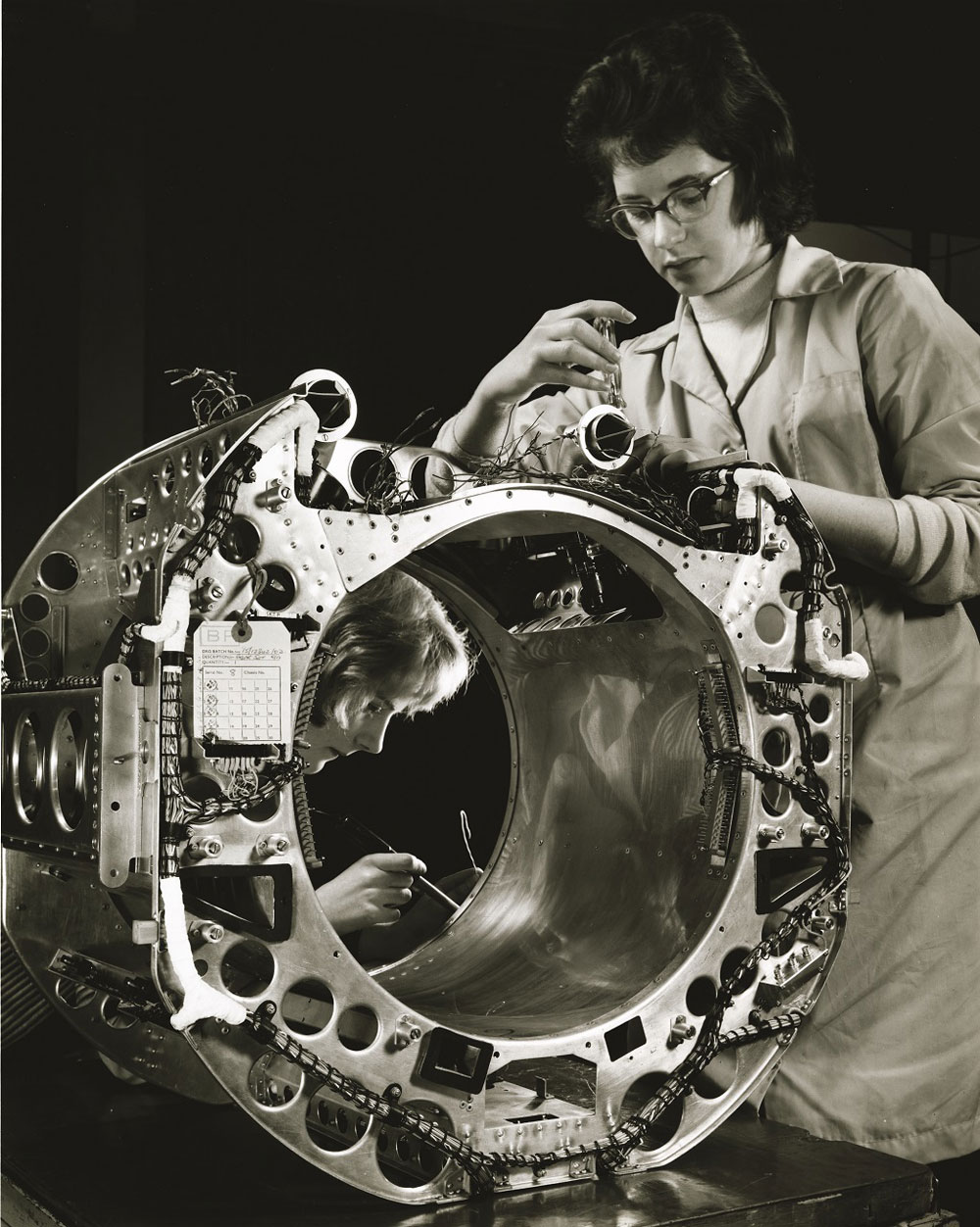

The gunsight was so critical, that a secret memo at the end WW2 described it as "the single most important equipment" introduced during the war. The very first gunsights were delivered on 5 December 1943, with 26 more completed by 1 January 1944, after which production steadily built to 1,000 units per month. The wartime output of gyro gunsights exceeded 9,500, with most equipping the guns of Lancaster, Spitfire and Hurricane aircraft. Company archives also show many women working in the production lines, forming the main workforce of the time. In 1944, the Daily Express reported on the RAF’s extraordinary success in the skies, saying: “Today the secret is out. RAF fighters have been using a new gunsight, officially known as the Gyro Gun Sight Mark Two. It is one of Britain’s great scientific achievements.”

Since then, more than 50,000 gyro gunsights have been supplied from Edinburgh to 25 countries around the globe. While the technology greatly enhanced the success of the Spitfire, it also acted as a springboard for the subsequent creation of a new generation of electronic systems. This included producing airborne radar, lasers and self-protection systems, cutting-edge versions of which are supplied today to an international customer base, keeping almost 2,000 highly skilled employees busy at Leonardo’s Edinburgh site.

In 1949, with the assistance of Sir Robert Watson-Watt, the ‘father’ of radar, our company was awarded a development contract for 1,000 Mhz Distance Measuring Equipment (DME) to be installed in the new de Havilland Comet – the world’s first jet airliner. The £500,000 contract provided a major boost to the company and to Scotland’s electronics industry.

By the middle of 1950, our prototype Distance Measuring Equipment (DME) was up and running, placing the company at the cutting edge of new technology.

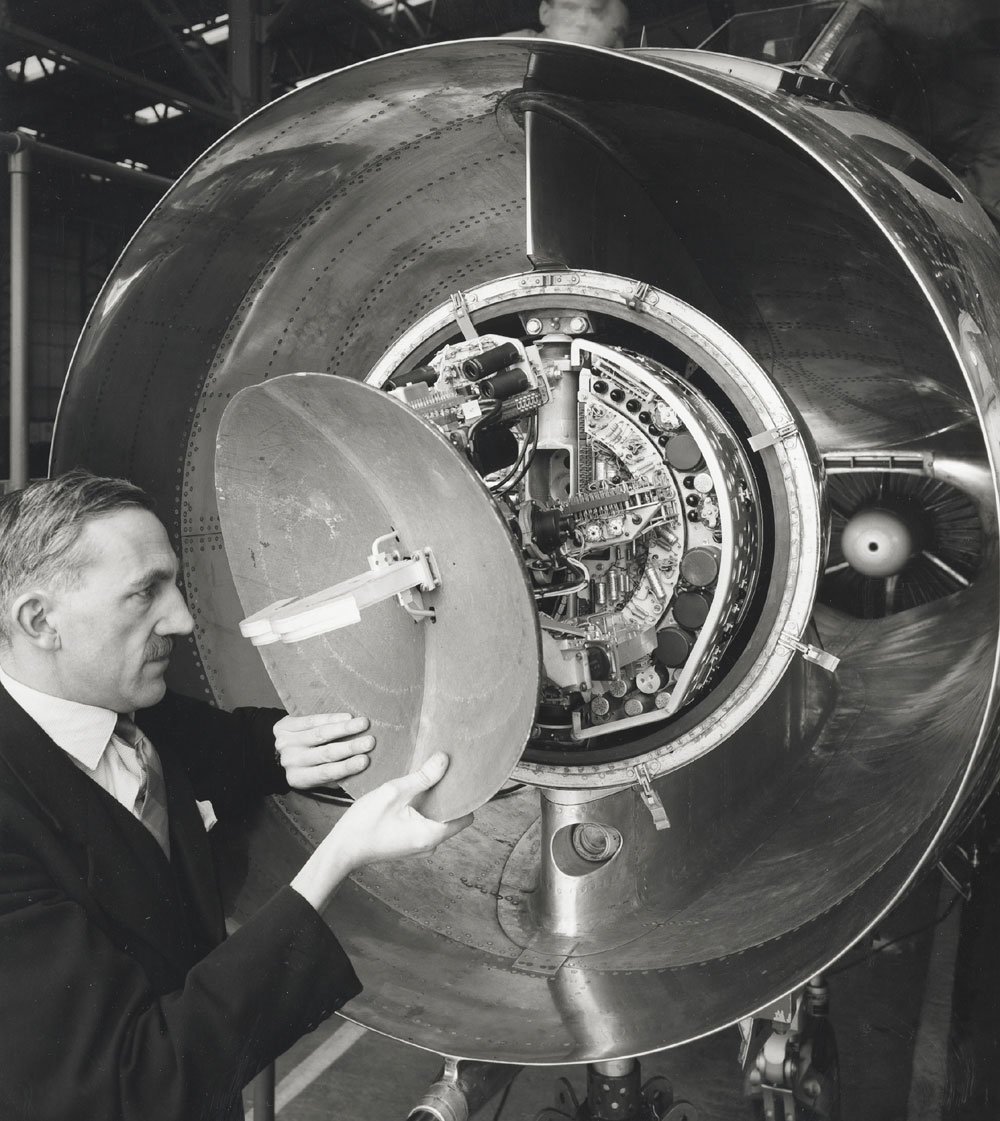

This was soon followed in 1957 by a contract to produce Ferranti’s AI23 Airpass radar for the English Electric Lightning, a supersonic fighter aircraft developed in the early 1950s. This was the first radar to be built at Crewe Toll, and the programme became a major success story in the history of our company.

In 1961, Ferranti introduced the Blue Parrot airborne radar system, developed at Crewe Toll. It was fitted to the Buccaneer attack aircraft and was built to detect Russian heavy cruisers.

In 1966, the company delivered the first of ten attitude reference systems and ground equipment to the ELDO (European Launcher Development Organisation) space programme. This was test fired from a range in Woomera, Australia.

By the late sixties, we had created a unique airborne laser ranger device. This fired a pulse of laser light at a target and measured the time taken to receive the scattered energy, allowing the range to be determined and displayed to a pilot.

The Laser Ranger and Marked Target Seeker (LRMTS) and the Laser Target Marker subsequently became major commercial successes for the company.

By the 1970s, the company was forging ahead with major aerospace projects including: radars for the Lightning and Buccaneer aircraft; support for the radar in the Phantom; the Inertial Navigation Attack System (INAS) in the UK Phantom and Harrier and in the US Marine Corps AV8a Harrier; inertial guidance packages for the European Space Programme; and airborne and ground-based laser equipment and gun sights for Canadian and Norwegian F5 aircraft.

One of the most significant developments was the company’s successful bid to provide inertial navigation systems, cockpit displays, airstream direction detectors and laser rangefinders for the European Multi Role Combat Aircraft (MRCA). This was Europe’s most ambitious multinational development programme to date, and would go on to become the Tornado – a multirole, twin-engine aircraft designed to excel at low-level entry through enemy defences.

Away from the day-to-day business activities, Ferranti Thistle football team, established in 1943, was renamed Meadowbank Thistle in 1974. Two decades later the team relocated to Livingston, and became Livingston FC, which is now an established team in the Scottish Premiership.

Though 1980 marked the end of an era, when the last of 50,000 gunsights manufactured was delivered to the RAF, new radar manufacturing facilities were established at Crewe Toll. This was the start of a golden age for the Edinburgh site, with an unprecedented number of new products, including the development of the first CAPTOR Radar and some of the world’s most advanced industrial lasers.

In 1981, the first Tornado Nose Radar was delivered to Germany and the first Jaguar nav/attack system was delivered to British Aerospace at Warton. A year later, the Edinburgh site received two Queen’s Awards – one for Technological Achievement and one for Export Achievement – for the Combined Map and Electronic Display (COMED).

Exports included delivery of the first Blue Fox radar for the Indian Navy’s Sea Harriers, contracts for the Mk.3 iteration of the Seaspray maritime surveillance radar for the German Navy’s Sea King helicopters and the South Korean Navy’s Lynx fleet, as well as heads up displays (HUD) for Royal New Zealand Air Force, and the 200th COMED for the America F/A-18.

Domestically, Ferranti delivered its 1,000th cockpit display system for the Tornado programme, while the Blue Vixen airborne radar entered service. It replaced the Blue Fox as the primary radar of later models of the Sea Harrier, and introduced a highly effective ‘look-down, shoot-down’ air superiority capability in conjunction with the AMRAAM missile.

In the space sector, Ferranti contributed to programmes for Ariane and Dornier through its inertial equipment and gyros.

A pioneer of workplace inclusion, with more than 170 disabled people employed in its Edinburgh factories, the company won its second ‘Fit for Work’ award in 1985.

In 1990, the Edinburgh site was part of the UK electronics businesses that were consolidated when GEC acquired Ferranti, merging it with Marconi to create the leading radar, electronic warfare and electro-optic business in the UK. A few months later, the radar development contract for the Eurofighter Typhoon was awarded to the company, worth £300 million.

The same year, following a series of test flights on Sea King helicopters, the Blue Kestrel radar took to the air in a development prototype Merlin helicopter.

In 1994, the new-generation fighter aircraft, Eurofighter Typhoon, embarked on its maiden flight, fitted with the radar ECR90 CAPTOR that was developed at Leonardo’s Edinburgh site. Today, Leonardo remains the industry consortium lead for the Typhoon electronic warfare and radar capability, including CAPTOR-E radar and the E-scan variants.

Following GEC’s acquisition in the early 1990s, the decade ended with Marconi becoming BAE Systems Avionics, after British Aerospace acquired GEC’s defence businesses, including Marconi Electronics Systems. This was the start of a programme of rebuilding the main avionics sites, including Edinburgh.

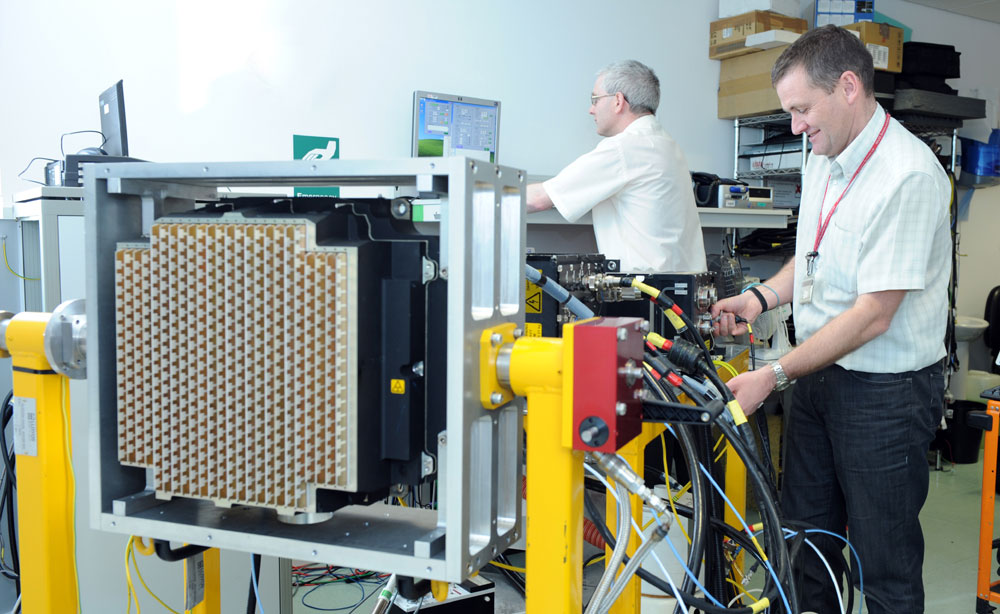

The new millennium saw a consolidation of Edinburgh’s sites into a single location at Crewe Toll. With the Flying Unit closing, continued investment went into Active Electronically Scanned Array (AESA) radars and lasers, in order to provide great precision, efficiency, detection and protection.

In 2001, HRH Prince Philip formally opened the redesigned facilities, which aimed to maximise the smooth flow of the manufacturing processes. The same year, we contributed the electro-optic system, including a high performance laser in the ‘eyesafe’ band, to BAE Systems and Thales’s JOANNA (JOint Airborne NavigatioN and Attack) technology demonstrator.

In 2006, our Seaspray 7500E radar, entered service with the US Coastguard’s 27-strong fleet of Hercules HC130 patrol planes. Seapsray has since becoming the class-leading maritime AESA radar, used by more than 30 international customers.

Two years later, the company won its first order for PicoSAR, a lightweight airborne ground surveillance radar. In the following two decades, PicoSAR has been installed on several fixed and rotary wing platforms around the globe.

In 2009, our Vixen 500E AESA radar (pictured above) was selected by TKC Aerospace Inc. to upgrade the Customs and Border Protection C-550 Citation Tracker Aircraft.

Outside of business-winning activities, we held our inaugural Robotic Games in Edinburgh in 2006, as part of the company’s promotion of Science, Technology, Engineering and Maths (STEM). The event featured Rampaging Chariot – radio controlled robots created by Leonardo engineer and famous test pilot, Peter Bennett MBE, who designed and built the award-winning Typhoon robots featured on the television programme Robot Wars. STEM activities were also undertaken with a range of local schools, colleges and Scottish universities, led by STEM Ambassadors from our Edinburgh site.

Throughout the decade, the Crewe Toll site raised £500k for charity through a range of fundraising initiatives. Charities that benefited included Edinburgh’s Royal Hospital for Children & Young People.

This was the decade when the company rebranded as Leonardo. The early part of the decade was notable for the company winning two Queen’s Awards; one in 2010 for International Trade, and one in 2011 for Enterprise in Innovation. These were followed by a series of major product developments and contracts throughout the 2010s.

2011 saw the launch of the Type 163 Ultra Lightweight Laser Designator and the Type 158 flexible, modular laser designed for integration into a range of small and medium-sized turret systems such as those on Unmanned Aerial Systems (UAS).

Three years later, a contract was signed for the Edinburgh site to develop the Captor E-Scan radar for the Eurofighter Typhoon. The same year, the company won a contract to equip Saab’s Gripen E fighters with the Raven AESA radar – one of the most advanced fighter radars in the world.

Having been unveiled in 2013, our Miysis Directed Infrared Countermeasure (DIRCM) system was successfully demonstrated as part of a NATO Trial in 2014. The technology provides dependable, persistent protection from IR-guided missiles, including advanced, all-aspect Man Portable Air Defence Systems.

In 2015, the Edinburgh business secured an order of 165 advanced targeting lasers for the F-35 Lightning II's Electro-Optical Targeting System.

Within early careers, Crewe Toll apprentices applied innovative use of sensor technology to help visually impaired users of a computerised power wheelchair (The Smart Platform, supplied by Smile Rehab) at Edinburgh's Royal Blind School find a way to navigate their way to the right classroom.

Elsewhere, Katie Archibald and Ross Gardiner, who each spent a year in industry at our Edinburgh site, won awards for their work during 2015 and 2016, while Lisa Daniel was named Apprentice of the Year (Level 4 and above) at the 2017 Scottish Apprenticeship Awards, and Thomas Sutherland won the 2019 IET Apprentice of the Year award.

There was also an award for Edinburgh engineer Euan Ward, who received an Industrial Fellowship from the Royal Commission, for improving the reliability of low cost radar systems.

The site’s commitment to fundraising saw it partner with several charities during the decade. Edinburgh staff raised £5,000 for Woodlands School for children with learning disabilities, £21,000 for Alzheimer Scotland, more than £10,000 for Cash for Kids, and over £14,000 for MND Scotland through bake sales, sponsored walks, a charity calendar, an annual Holyrood Fun Run, zip lining over the Clyde and pub quizzes.

We marked the end of an era in 2018, when the final gyro gunsight was produced at Crewe Toll, 75 years after the first one was delivered by the company.

In 2019, Mark Stead took over management of Leonardo’s Edinburgh site, picking up the reigns from Alastair Morrison.

While Covid-19 struck at the start of the 2020s, our engineers in Edinburgh, along with colleagues across Leonardo’s other UK sites, turned their engineering skills to producing protective face shields for NHS staff and critical workers, including Edinburgh’s Harmeny Education Trust, using additive manufacturing and 3D printing capability.

But the pandemic did not stop the company working hard to deliver against customer requirements and secure new contacts. In May 2020, it was announced that Leonardo’s Osprey radar would be installed on the UK Maritime and Coastguard Agency two customised Beechcraft King Air aircraft, to support missions such as search and rescue, border protection, fishery and pollution patrols. A few months later, a contract was signed to develop the next generation of radar for the RAF’s Eurofighter Typhoons, extending our long-term relationship with Eurofighter.

During 2021, Leonardo committed to supply the Slovenian Defence Ministry with its Type 163 Laser Target Designator, and our Innovation and Technology Incubator Centre in Edinburgh teamed up with O2 to investigate innovative applications of private 5G technology in the defence and security industry.

The following year, we signed a £260m contract to deliver R&D, as well as key antenna, processor and APSC components for the HENSOLDT-led ECRS Mk1 radar for German and Spanish Typhoons, while Edinburgh was amongst our first digital electronics factories to go live.

Throughout the early 2020s, the Edinburgh site has also played a key role in Leonardo’s partnership with the UK Ministry of Defence, BAE Systems, Rolls Royce and MBDA as part of ‘Team Tempest’ in the development of technologies, knowledge, skills and expertise for the Next Generation Combat Air System capable of operating in the 2040+ environment. This includes supporting the production of capability for a sixth generation fighter aircraft under the new Global Combat Air Programme (GCAP), which will continue throughout the rest of the 2020s and beyond.

Our support for the communities which surround our sites was recognised by the British Chambers of Commerce when we were named as a ‘Business Hero’ in 2020. Furthermore, our commitment to innovation led to Leonardo’s Edinburgh business securing another Queen’s Award in 2022 – for Enterprise – in the Innovation category.

Individuals were also celebrated for their contributions to industry. While undertaking her year in industry with Leonardo in Edinburgh, Katie Walker won the Innovation Prize at the 2020 Engineering Development Trust’s Year in Industry ‘Contribution to the Business’ (CTTB) Awards. Two years later, Anna Hart won the 'Rising Star' category at the 2022 WorldSkills UK Equity, Diversity and Inclusion Heroes Awards, which celebrate individuals championing inclusion and diversity (I&D) within business, while Design Engineering Graduate Apprentice Ross Pringle, was named national winner of the Institution of Mechanical Engineers’ (IMechE) Bryan Hildrew Apprentice of the Year Award.

We are proud to have partnered with several local charities in the past three years, with Social Bite, Harmeny Education Trust and LifeCare all benefiting from fundraising initiatives.